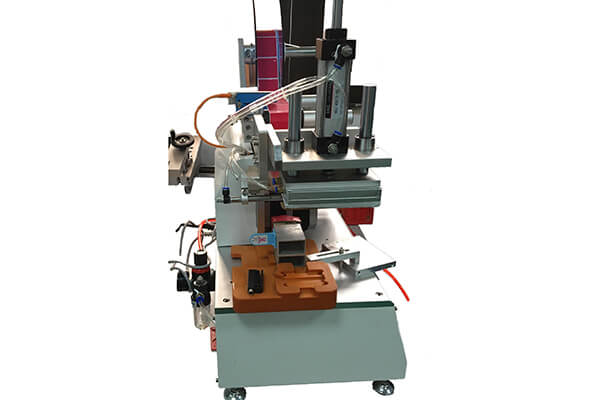

This semi automatic flat lid labeling machine adpot adhesion label method of labeling to achieve a variety of flat surface labeling, such as cosmetics flat bottles, packaging, plastic cover labeling and so on.Can be applied to the uneven surface labeling by customized, such as concave plane, circular surface labeling and so on. Change the fixture can be applicable to a variety of irregular product labeling.

Optional ribbon printer or inkjet printer, print on the label production date and batch number to achieve coding - labeling integration. Can be used to support a variety of packaging lines.

What is the features of our flat lid labeling machine?

1.Suitable for labeling various flat surface container.

2.Can install coding/inkjet printer (optional).

3.Meet the GMP production requirements, The main material using stainless steel and advanced aluminum alloy

4.Stable performance, Adopt by PLC + optical fiber sensor control system to support long-term work.

5.Production and management convenience, Machine with the labeling count, power saving mode, photoelectric tracking tags and other functions

Technical parameters

Labeling speed | 15-30/minute |

Labeling accuracy | ±0.5mm |

Label width | 15-150mm |

Label length | 10-100mm |

Label roll inner diameter | 76mm |

Max label roll outer diameter | 280mm |

Applicable scope of container | L:20-200 W:20-150 H:0.2-120mm |

Voltage | 220V 50Hz |

Power | 500W |

Package size | 850*430*750 |

Gross weight | 50Kg |